Polyurethane Wheels

Polyurethane Wheels Specification

- Classification

- Polyurethane Wheels

- Type

- Industrial Wheel

- Grade

- Industrial Grade

- Purity

- 99%

- Application

- Material Handling, Trolleys, Caster Wheels, Conveyors

- Color

- Red

- Form

- Solid Wheel

- Size

- 100mm, 150mm, 200mm (available in multiple sizes)

- Material

- Polyurethane (PU)

About Polyurethane Wheels

We have attained the market trustworthiness by manufacturing and supplying our clients a commendable array of Polyurethane Wheels. These wheels are mainly used in mechanical and electrical industries for removing the bond separation. The provided wheels are manufactured under the stern guidance of our skilled professionals using quality-assured polyurethane and sophisticated techniques in tune with set industrial standards. Available in various specifications as per the precise needs of clients, these Polyurethane Wheels can be purchased from us at most competitive prices.

Features:

Easy to install

Abrasion resistance

Application specific design

Enhanced durability

Durability and High Load Capacity

Polyurethane Wheels are known for their remarkable resistance to wear, abrasion, and chemicals. The solid construction and high-purity material ensure reliability when handling heavy loads in industrial environments. Their robust performance reduces the frequency of replacements, making them a cost-effective choice for businesses.

Applications Across Industries

These industrial polyurethane wheels are suited for use in trolleys, caster wheels, conveyors, and general material handling. Their ability to provide smooth, quiet movement enhances workplace efficiency, while the availability of multiple sizes enables their integration into various equipment designs.

Quality Assurance from Trusted Indian Manufacturer

As a leading manufacturer and supplier in India, we adhere to stringent quality controls at every production stage. Our polyurethane wheels meet high industrial standards, ensuring clients receive durable and dependable products tailored for their needs.

FAQs of Polyurethane Wheels:

Q: How are industrial polyurethane wheels manufactured?

A: Our polyurethane wheels are produced through a specialized molding process that ensures consistent density and structural integrity. High-purity (99%) polyurethane is poured into molds and cured to form solid wheels, resulting in excellent durability and performance for industrial applications.Q: What makes these wheels suitable for material handling and conveyors?

A: These wheels possess outstanding load-bearing capability, wear resistance, and smooth rolling properties, making them ideal for demanding uses such as trolleys, caster wheels, and conveyor systems. Their solid PU construction provides dependable performance in material handling operations.Q: When should I choose polyurethane wheels over traditional rubber or metal wheels?

A: Polyurethane wheels are recommended when your operations require superior abrasion resistance, quieter movement, and less floor marking compared to metal or rubber wheels. They are especially effective in environments where longevity and minimal downtime are crucial.Q: Where can these polyurethane wheels be applied?

A: They are versatile and suitable for various applications, including factory trolleys, industrial carts, conveyor systems, and caster assemblies across multiple industries, from warehousing to manufacturing.Q: What is the process for selecting the correct size and type for my needs?

A: Consider the load capacity, operational environment, and required wheel size (available in 100mm, 150mm, and 200mm). Our team can assist you in choosing the optimal specification to match your equipment and workload requirements.Q: How do polyurethane wheels benefit industrial operations?

A: Their resistance to abrasion, high load capacity, and minimal maintenance requirements lead to reduced downtime and operational costs, offering long-term value for material handling processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polyurethane Products Category

Industrial Polyurethane Products

Application : Other, Mechanical parts, Seals, Rollers, Bushes, Sheets, Gaskets, Wear and tear parts

Classification : Other, Polyurethane Products

Color : Other, Red, Yellow, Custom colors available

Size : Customized as per requirements

Form : Other, Molded Parts, Sheet, Bar, Roller

Material : Polyurethane (PU)

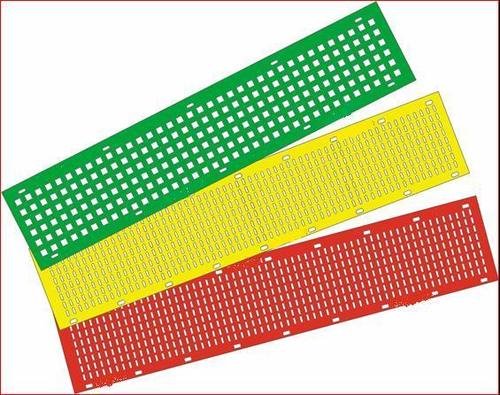

Polyurethane Flip flops Screen

Application : Other, Screening, Mining, Quarrying, Aggregate Processing

Classification : Other, Polyurethane Screen

Color : Yellow

Size : Customizable as per requirement

Form : Other, Screen Panel

Material : Polyurethane (PU)

Polyurethane Vibrating Screen

Application : Other, Screening and Filtering in Mining, Quarrying, Coal, and Metallurgy

Classification : Other, Screen Mesh

Color : Yellow

Size : Customized

Form : Other, Panel / Sheet

Material : Polyurethane

GST : 19AGCPB3365M1ZA

|

T. BANERJEE INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry