Polyurethane Vibrating Screen

Polyurethane Vibrating Screen Specification

- Classification

- Screen Mesh

- Type

- Vibrating Screen

- Grade

- Industrial

- Application

- Screening and Filtering in Mining, Quarrying, Coal, and Metallurgy

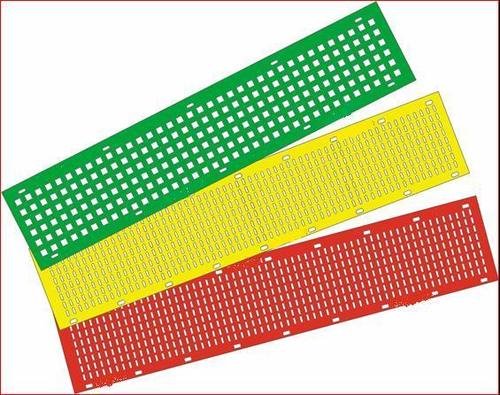

- Color

- Yellow

- Form

- Panel / Sheet

- Size

- Customized

- Material

- Polyurethane

- Width

- Range as per requirement, typically up to 2 meters

- Corrosion Resistance

- Excellent, suitable for wet applications

- Surface Finish

- Smooth or textured as per model

- Thickness

- 10 mm to 50 mm (or as specified by customer)

- Installation

- Modular fitting, easy to replace and maintain

- Open Area

- Optimized for maximum screening efficiency

- Tensile Strength

- High tensile and tear strength

- Weight

- Lightweight for easy handling

- Life Span

- Long service life, abrasion and wear resistant

- Aperture Size

- 0.1 mm to 100 mm (customized as per order)

About Polyurethane Vibrating Screen

We are engrossed in providing supreme quality Polyurethane Vibrating Screen. The offered screen is used for screening and providing vibration proof surface to various materials. This screen is designed and manufactured at our highly advanced manufacturing unit by our seasoned technocrats using premium quality polyurethane and advanced techniques in adherence with set industry standards. Further, we are providing this Polyurethane Vibrating Screen to the clients at most reasonable price within promised time frame.

Features:

-

Easy to install

-

Precise dimension

-

Robustness

-

Abrasion resistance

Superior Screening Efficiency

Designed with optimized open areas and customizable apertures, the Polyurethane Vibrating Screen delivers exceptional screening outcomes for demanding industries. Its advanced panel structure ensures maximum particle separation and minimal clogging, enhancing throughput and accuracy in material classification.

Robust and Resilient Construction

Made from high-quality polyurethane, the screen provides outstanding tensile and tear strength, guaranteeing durability under continuous vibration and heavy loads. The materials abrasion and wear resistance permits long-term use, reducing frequent replacement and down-time, making it a reliable choice for industrial operations.

Effortless Installation and Maintenance

With a modular fitting system and lightweight design, handling and installing panels is hassle-free. Replacement and maintenance require minimal time and effort, allowing rapid servicing and reducing operational interruptions. The screens are available in panel or sheet form to accommodate various installation preferences.

FAQs of Polyurethane Vibrating Screen:

Q: How is the Polyurethane Vibrating Screen installed and replaced?

A: The screen features a modular fitting system, allowing for quick and straightforward installation and replacement. Its lightweight panels can be easily handled and fitted, minimizing downtime and labor requirements during maintenance.Q: What aperture sizes are available for these screens?

A: Aperture sizes range from 0.1 mm to 100 mm and can be fully customized according to specific project demands, supporting a variety of screening and filtering applications in mining, quarrying, and related industries.Q: When should I choose a smooth or textured surface finish?

A: Smooth surface finishes are best for materials prone to sticking, while textured finishes are ideal for enhanced particle movement and improved screening performance in certain applications. Selection depends on material characteristics and operational preferences.Q: Where are these screens suitable for use?

A: Polyurethane Vibrating Screens are suitable for industrial environments such as mining, quarrying, coal processing, and metallurgy, especially where wet applications and corrosive conditions are present.Q: What process is used for customizing the screens dimensions?

A: Dimensions, including width, thickness, aperture size, and panel size, are tailored according to client specifications during production. Customers communicate their requirements to the manufacturer or supplier to receive screens that fit their system precisely.Q: How does the screens corrosion resistance benefit operations?

A: The screens excellent corrosion resistance makes it ideal for wet and abrasive environments. This property extends service life and reduces maintenance frequency, ensuring consistent operation and cost savings over time.Q: What are the primary usage and advantages of polyurethane over traditional screen materials?

A: Polyurethane offers greater abrasion resistance, lighter weight, and longer lifespan compared to metal screens, making it highly advantageous for high-impact and corrosive processes commonly found in industrial screening and filtering.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polyurethane Products Category

Industrial Polyurethane Products

Material : Polyurethane (PU)

Purity : Other, High

Color : Other, Red, Yellow, Custom colors available

Size : Customized as per requirements

Classification : Other, Polyurethane Products

Application : Other, Mechanical parts, Seals, Rollers, Bushes, Sheets, Gaskets, Wear and tear parts

Polyurethane Wheels

Material : Polyurethane (PU)

Purity : Other, 99%

Color : Other, Red

Size : 100mm, 150mm, 200mm (available in multiple sizes)

Classification : Other, Polyurethane Wheels

Application : Other, Material Handling, Trolleys, Caster Wheels, Conveyors

Polyurethane Flip flops Screen

Material : Polyurethane (PU)

Purity : Other, 99%

Color : Yellow

Size : Customizable as per requirement

Classification : Other, Polyurethane Screen

Application : Other, Screening, Mining, Quarrying, Aggregate Processing

GST : 19AGCPB3365M1ZA

|

T. BANERJEE INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry