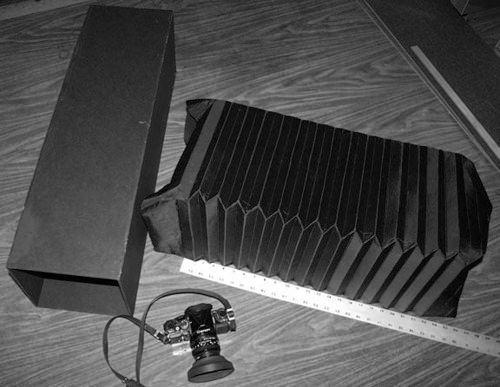

Pipeline Bellow

Pipeline Bellow Specification

- Max. Temperature

- up to 400C

- Flange

- ANSI/DIN Standard

- Media

- Water, Steam, Gas

- Surface Treatment

- Polished

- Head Code

- Round

- Material

- Stainless Steel

- Technique

- Hot Rolled

- Type

- Expansion Bellows

- Connecting Type

- Flanged

- Shape

- Cylindrical

About Pipeline Bellow

Owing to our expertise in this field, we have been able to offer plethora of Pipeline Bellow. The offered bellow is used in several industries for controlling the movement of water at high pressure. This bellow is designed and manufactured by our seasoned technocrats using premium quality raw materials and advanced techniques in adherence with set industry standards. Further, we are providing this Pipeline Bellow to the clients at most reasonable price within promised time frame.

Features:

Easy to install

Precise dimension

Robustness

Abrasion resistance

Optimal Expansion Control

These cylindrical expansion bellows are engineered to absorb and compensate for thermal expansion within pipelines, protecting infrastructure from stress and deformation. Their robust stainless steel build and hot-rolled technique make them suitable for high-pressure environments and frequent temperature fluctuations.

Versatile Media Compatibility

Capable of handling water, steam, and gas, the bellows offer broad utility across various industries, including power generation, chemical processing, and water treatment. The polished surface enhances corrosion resistance, contributing to reliable performance over prolonged periods.

Industry-Standard Connectivity

Equipped with flanged ends conforming to ANSI/DIN standards, these bellows enable seamless connection to existing pipeline networks. This standardized approach simplifies installation and maintenance, thereby reducing downtime and operational complexity.

FAQs of Pipeline Bellow:

Q: How are Pipeline Bellows installed within a piping system?

A: Pipeline Bellows are designed with flanged connections conforming to ANSI/DIN standards, allowing for straightforward bolted installation between matching pipe flanges. Installation should be performed according to the manufacturers guidelines, ensuring precise alignment and gasket sealing to maximize performance and safety.Q: What is the main benefit of using stainless steel, hot-rolled expansion bellows?

A: Stainless steel provides excellent resistance to corrosion, temperature extremes, and mechanical wear. The hot-rolled manufacturing technique enhances the materials strength and flexibility, which are critical for expansion bellows operating under thermal stress and pressure fluctuations.Q: When should expansion bellows be used in pipelines?

A: Expansion bellows are necessary when pipeline systems are exposed to thermal expansion, vibrations, or movement due to fluid flow or external factors. They mitigate stress and prevent damage, especially in environments where temperature can reach up to 400C, as seen in steam, water, and gas applications.Q: Where are these Pipeline Bellows typically supplied from and used?

A: These bellows are manufactured and supplied from India and are commonly used in sectors such as power plants, chemical industries, and water facilities, where reliable expansion control is essential for pipeline integrity and efficiency.Q: What is the process for treating the bellows surface, and why is it beneficial?

A: The bellows undergo a polished surface treatment, which enhances their corrosion resistance and improves appearance. This process also facilitates easier cleaning and prolongs the components service lifespan in harsh industrial environments.Q: How do expansion bellows contribute to pipeline safety and longevity?

A: Expansion bellows absorb mechanical strain and thermal movement, preventing pipeline fatigue, leaks, or ruptures. This protective function reduces maintenance needs, extends the pipelines operational life, and ensures safer transport of steam, water, or gas.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bellows & Expansion Joints Category

Bed Cover Bellow

Max. Temperature : 80C

Type : Others, Bed Cover Bellow

Shape : Other, Rectangular / Customized

Connecting Type : Others, Flange / Clamp

Flange : Available as per requirement

Media : Other, Air, Dust, Light Particulates

Rubber Bellows

Max. Temperature : Up to 120C

Type : Others, Bellows

Shape : Other, Cylindrical/Accordion

Connecting Type : Others, Flange/Union

Flange : Drilled Flange Ends

Media : Other, Water, Air, Chemical Fluids

Rectangular Section Bellow

Max. Temperature : Up to 120C (Material Dependent)

Type : Others, Expansion Bellows

Shape : Other, Rectangular

Connecting Type : Others, Flanged or Clamped

Flange : Available with MS, SS, or Aluminum Flanges

Media : Other, Air, Dust, Fumes, Gases

CNC Ball Screw Bellow

Max. Temperature : 120C

Type : Others, Bellow Cover

Shape : Other, Round

Connecting Type : Others, Clamp / Flange

Flange : Steel / Aluminum

Media : Other, Air, Dust, Oil, Coolant

GST : 19AGCPB3365M1ZA

|

T. BANERJEE INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry