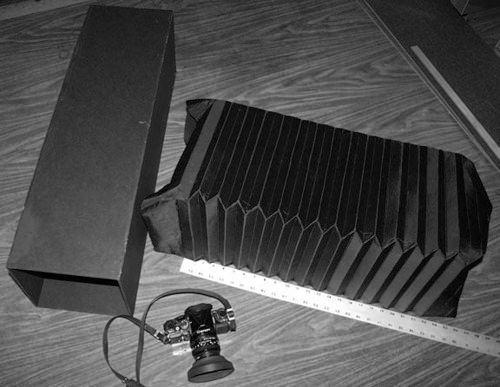

Rubber Bellows

Rubber Bellows Specification

- Max. Temperature

- Up to 120C

- Media

- Water, Air, Chemical Fluids

- Head Code

- Round

- Surface Treatment

- Smooth/Polished

- Flange

- Drilled Flange Ends

- Material

- Rubber

- Technique

- Molded

- Type

- Bellows

- Connecting Type

- Flange/Union

- Shape

- Cylindrical/Accordion

- Working Pressure

- Up to 16 bar

About Rubber Bellows

Our technical excellence has made us to supply a qualitative range of Rubber Bellows. These bellows are used in automotive alignment equipment, seat spring, industrial machinery, shock absorbers, vibrating conveyors and many more. The offered bellows are manufactured using superlative quality rubber and innovative techniques under the perfect guidance of adroit experts. According to specific needs of clients, we offer these Rubber Bellows in various specifications and at market leading prices.

Features:

Easy installation

Abrasion resistance

Durability

Perfect finish

Exceptional Vibration Absorption

Our rubber bellows are expertly engineered to absorb mechanical vibrations in piping systems, HVAC, and pumps. By reducing movement transmission, they protect your infrastructure and enhance operational reliability, leading to longer equipment lifespan and fewer maintenance concerns.

Highly Durable and Weather Resistant

Constructed with premium rubber reinforced by nylon or polyester cord, these bellows possess superb elasticity and remarkable recovery, even in harsh operating environments. Their chemical and weather resistance ensures consistent performance indoors or outdoors, under extreme temperatures or prolonged exposure.

FAQs of Rubber Bellows :

Q: How are rubber bellows installed in piping systems?

A: Rubber bellows are typically installed using flange or union connections with drilled flange ends, ensuring a secure and leak-proof fit. Installation can be completed during new system assembly or retrofitted into existing infrastructure by aligning the bellows with the pipe flanges and tightening the bolts as per specifications.Q: What are the main benefits of using rubber bellows in HVAC and pump applications?

A: These bellows minimize the transfer of noise and vibration, accommodate thermal expansion, and compensate for misalignment in piping. This not only extends the life of equipment but also improves system reliability and reduces maintenance requirements.Q: Where should rubber bellows be used within an industrial or plumbing setup?

A: Rubber bellows are ideally used at points of vibration or movement, such as near pumps, compressors, and in sections of piping exposed to temperature fluctuations. They are suitable for systems that carry water, air, or chemical fluids.Q: What makes these rubber bellows suitable for harsh environments?

A: Their construction from high-grade rubber with nylon or polyester cord reinforcement provides resistance to a wide range of chemicals, weather conditions, and temperatures up to 120C. This combination guarantees longevity and performance even under challenging environmental conditions.Q: When should rubber bellows be replaced or maintained?

A: Regular inspections are recommended, especially in systems subject to extreme pressure or chemical exposure. Replace bellows if you notice visible wear, cracking, or a loss of elasticity to maintain system integrity and prevent leaks or failures.Q: What is the manufacturing process of these bellows?

A: Each bellow is produced using a molding technique, which ensures uniform wall thickness and high structural integrity. Advanced industry standards are followed throughout the process to meet performance and safety requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bellows & Expansion Joints Category

Rectangular Section Bellow

Technique : Others, Hot Press Molding / Fabric Reinforced Molding

Head Code : Other, Rectangular

Surface Treatment : Other, Coated / Uncoated, Oil Resistant Finish

Type : Others, Expansion Bellows

Connecting Type : Others, Flanged or Clamped

Flange : Available with MS, SS, or Aluminum Flanges

CNC Ball Screw Bellow

Technique : Others, Heat Sealing

Head Code : Round

Surface Treatment : Other, Black Finish

Type : Others, Bellow Cover

Connecting Type : Others, Clamp / Flange

Flange : Steel / Aluminum

Bed Cover Bellow

Technique : Others, Thermoforming / Welding

Head Code : Square

Surface Treatment : Other, Smooth Finish

Type : Others, Bed Cover Bellow

Connecting Type : Others, Flange / Clamp

Flange : Available as per requirement

Vibration Dampening Bellow

Technique : Others, Molded and Reinforced

Head Code : Round

Surface Treatment : Other, Black Coated/Polished

Type : Others, Vibration Dampening Bellow

Connecting Type : Others, Flanged

Flange : Standard MS Flange

GST : 19AGCPB3365M1ZA

|

T. BANERJEE INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry