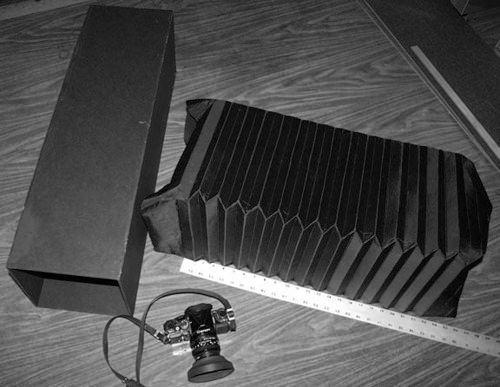

Flexible Rubber Bellows

Flexible Rubber Bellows Specification

- Media

- Water, Air, Oil, Chemicals (Based on Rubber Type)

- Max. Temperature

- 120C to 180C (Depending on Material)

- Surface Treatment

- Powder Coated / Painted / As Required

- Head Code

- Round

- Flange

- Mild Steel / Stainless Steel (IS 2062/SS304/SS316 options)

- Technique

- Moulded / Fabric Reinforced

- Type

- Flexible Rubber Bellows

- Connecting Type

- Flange / Threaded

- Shape

- Cylindrical / Round

- Working Pressure

- 10 bar to 25 bar (Depending on Size and Material)

About Flexible Rubber Bellows

We are among the noteworthy manufacturers and suppliers of Flexible Rubber Bellows. The provided bellows are used in pipelines system for taking misalignment and thermal expansion of pipe lines. Available in various specifications to suit varied demands of clients, these bellows are designed and manufactured at our well-equipped manufacturing unit using quality-tested rubber and innovative techniques in conformance with set industrial standards. Furthermore, we offer these Flexible Rubber Bellows to the clients at industry leading prices.

Features:

High elasticity

Abrasion resistance

Durability

Perfect finish

Superior Flexibility and Durability

These bellows excel due to their moulded or fabric-reinforced construction, which combines lasting durability with the intrinsic flexibility required in dynamic piping systems. Designed to absorb movement, vibration, and noise, they help prolong the lifespan of connected equipment, making them an essential solution in demanding industrial settings.

Customizable for Every Application

Our flexible rubber bellows can be tailored with various connection methods, including flange or threaded ends, and surface treatments like powder coating or painting. This flexibility allows integration into a wide range of piping systems, handling different pressures, temperatures, and fluid media ensuring compatibility with water, air, oil, or chemicals.

FAQs of Flexible Rubber Bellows :

Q: How are flexible rubber bellows installed in a piping system?

A: Flexible rubber bellows are typically installed by connecting either end to the piping system using flange or threaded connections. Installation requires correct alignment and tightening for a secure seal, ensuring the bellows accommodate movement and vibration as specified.Q: What is the maximum temperature these bellows can handle?

A: Depending on the rubber material used, our bellows can withstand temperatures ranging from 120C to 180C. The exact limit is determined by the selected rubber composition to match your operating conditions.Q: When should I use fabric reinforced instead of moulded bellows?

A: Fabric reinforced bellows are preferred in applications where enhanced mechanical strength and resistance to pressure or movement are necessary. Moulded types are suitable for standard flexibility and moderate pressure settings.Q: Where can these bellows be used effectively?

A: They are effective in industries that require vibration isolation and flexibility in fluid transfer, such as water treatment plants, chemical facilities, HVAC systems, and oil refineries. The choice of media and flange material ensures suitability for a broad spectrum of applications.Q: What is the process for customizing a rubber bellow for specific requirements?

A: Customization starts by identifying operational conditions such as temperature, pressure, required flexibility, and the nature of the fluid media. The bellow is then manufactured using the appropriate rubber type, shape, reinforcement, and surface treatment to meet your needs.Q: What are the main benefits of using flexible rubber bellows?

A: The primary benefits include absorption of thermal and mechanical movement, reduction of vibration and noise, and compensation for misalignments. This protects piping systems and equipment, enhancing reliability and longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bellows & Expansion Joints Category

CNC Ball Screw Bellow

Flange : Steel / Aluminum

Max. Temperature : 120C

Surface Treatment : Other, Black Finish

Head Code : Round

Type : Others, Bellow Cover

Technique : Others, Heat Sealing

Rectangular Section Bellow

Flange : Available with MS, SS, or Aluminum Flanges

Max. Temperature : Up to 120C (Material Dependent)

Surface Treatment : Other, Coated / Uncoated, Oil Resistant Finish

Head Code : Other, Rectangular

Type : Others, Expansion Bellows

Technique : Others, Hot Press Molding / Fabric Reinforced Molding

Expansion Joint

Flange : FLANGE END

Max. Temperature : 20 Degree C to +200 Degree C Celsius (oC)

Surface Treatment : Other, Nickel Plated

Pipeline Bellow

Flange : ANSI/DIN Standard

Max. Temperature : up to 400C

Surface Treatment : Other, Polished

Head Code : Round

Type : Others, Expansion Bellows

Technique : Others, Hot Rolled

GST : 19AGCPB3365M1ZA

|

T. BANERJEE INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry